M-TUNE INSTALLATION & INFORMATIONPlease read through the following instructions completely to make sure you do not overlook any of the required procedures for the complete and safe installation of the M-Tune kit.CHIP BOARD SETTINGWhen ordering the M-Tune, you were required to select a Tune file to be initially installed on the DME chip by us. Those different tune files were based on engine displacement and fuel injector size. Each of those Tune Files contained multiple maps for different fuels and running modes such as valet. In order to select the appropriate map or maps for the M-Tune to operate on, you need to set the DME Chip Board Dip Switch up. The current list of tune files are the following.

The DME Chip Board has a small Dip Switch located on it and needs to be set to the appropriate position to select the maps that you want to run. Let's use the following example. Lets say you selected Tune 1 (2.5L and 80# Injectors) when ordering the kit and you want the run maps 3 & 4 for Pump & E85 Fuels. You would use the Tunes 3 & 4 position pictured below to set your Dip Switch to on the Chip Board appropriately.

Since your dip switch position is now set to run a specific pair of maps with a odd and even number, by default it runs on the odd number map. So if running Tunes 13 & 14, it will run on tune 13. By installing the supplied jumper wire into the coding plug on the DME harness, it will engage or run on the even numbered map, or in this case map 14. If you cut the supplied jumper wire and install a toggle switch there, you can toggle back and forth between map 13 and 14 with the flip of a switch. You may want to locate this switch in a not so obvious spot to keep unwanted hands off of it. THE MAP SENSOR The MAP sensor has a vacuum/boost port on its underside. This port needs to be connected to the port on the intake manifold. Typically, T-ing off of the vacuum line going to the fuel pressure regulator provides good results. Additionally, the length of tubing from the MAP sensor to the intake manifold should be kept less than three feet long. This helps keep the MAP sensor response time very fast. The MAP sensor comes with a three-wire harness, that is color-coded:

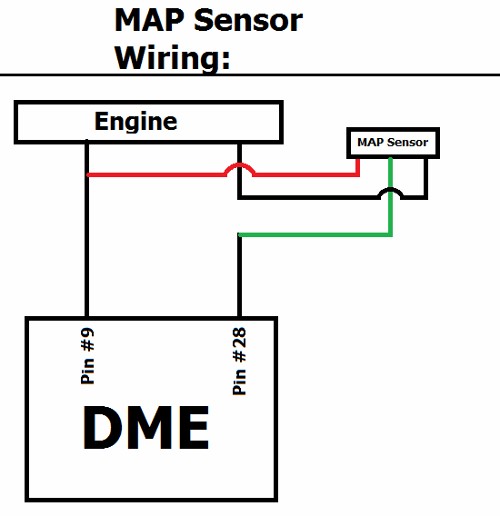

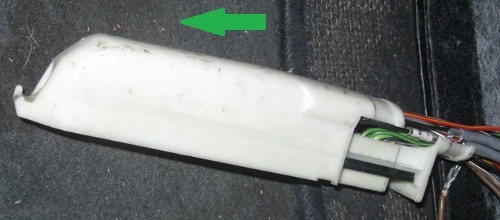

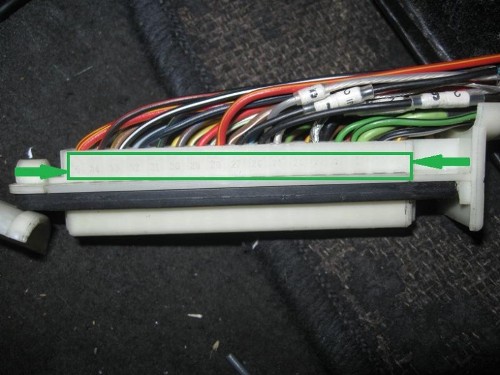

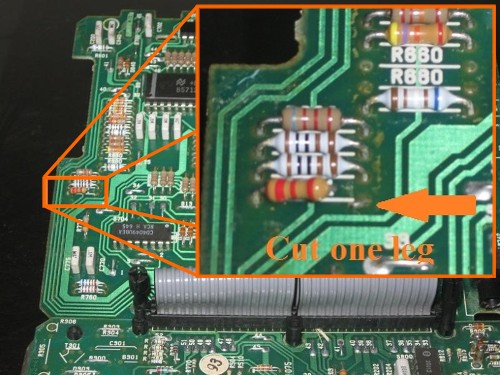

The MAP sensor harness is long enough to place the sensor in the engine-bay and run the wires through the firewall boot/seal to the DME. The Red power wire is tapped, that is - do not cut the DME's respective wire, just remove some of the DME wires insulation and connect the MAP sensor wire. As always, we recommend soldering, not T-type or "vampire" clips. A poor connection here can significantly reduce the MAP sensor signal. For the Green signal wire, the DME wire 28 needs to be cut, and then connect the MAP sensor Green wire to the wire going to the DME. Then connect the MAP sensor Black wire to the cut wire that goes towards the engine. ***The DME wiring colors could be different depending on the build date of your car*** Here is a quick visual to follow:  Now that the MAP sensor is wired in, a simple voltage check will confirm that it is working properly: With the ignition on, measure the voltage on the red wire to ground. You should see +5volts. Now measure the voltage on the green wire. This should read ~1.6 volts (this will vary slightly depending on altitude). If either wire does not read correctly, double-check your connections and that they are going to the proper wires in the DME harness. MOUNTING THE MAF SENSOR  THE DME PLUGIn order to properly identify DME's pin # 28, it is necessary to disassemble the DME plug. Once the cover is off, the pin numbering becomes visible: Once you remove the small screw on the end, the back of the plug will slide off unveiling the numbers seen here boxed in green. Locate #28 and that's your wire.    Pin # 28 tends to be black on the 951. Double-check that you cut the correct wire by using a volt-ohm meter to verify continuity between pin # 28 and the wire you plan on cutting! MODIFYING THE DMEThe second step necessary to install the MAP Sensor is removing/cutting a resistor in the DME itself. This is necessary for the DME to properly read the MAP sensor. The resistor on the same side of the DME that the EPROM is. If you are comfortable with soldering you can de-solder the resistor and remove it. Alternatively, you can simply cut one of the resistors legs, and bend the resistor out of the way - making sure it does not come into contact with the DME board:   Depending on the year of your DME, the body of the resistor might be a different color. ***Cutting/removing this resistor does not affect normal function of the DME, regardless of software*** FUEL PRESSUREThe fuel system needs to be set at 3.0 bar (43 psi). You can do this with the fixed rate Bosch 3.0 bar fuel regulator or by an adjustable fuel regulator that is set to 43 psi with the car idling and the vacuum hose temporarily disconnected from the fuel regulator. Reconnect the vacuum hose once the pressure is set. DME FQS SWITCHThis new M-Tune has new FQS (Fuel Quality Switch) values which are different from the stock values you may be used to seeing and there is no ignition timing adjustment, only fuel. M-Tune MAF KIT FQS SETTINGSN (Chip has a black and white label stating LR/M-TUNE on it. Chip sits on a chip board with dip switches)

951 MAF Tune MAF KIT FQS SETTINGS (Chip has a Red, Black and White label stating LR 951 MAF TUNE on it and does not have a chip board underneath it.)

If you're not familiar with the DME FQS switch, you can learn more about it Here . Ignore the FQS settings on this page as they are for stock DME's, not ones running the the M-Tune. Those setting are on the chart above. 24 PIN TO 28 PIN DME CONVERSIONThe M-Tune requires a 28 Pin DME. If you have a 24 Pin DME, it can be modified to accept the 28 Pin Chip Board. Either Lindsey Racing can perform the modification for you for a price of $50, or you can request the parts from us to do the modification yourself. The conversion procedure requires 3 steps. 1. Solder in the additionl pair or pins (allows you to install the 28 pin chip board) 2. Install a jumper wire (tells the DME that it now needs to recognize the 28 pin chip) 3. Cut a transistor (required for the addition of the MAP sensor) To download the procedure for the DME modification, CLICK HERE . |

Secure Checkout