COMPARING FLOW NUMBERSHere at Lindsey Racing we occasionally get asked about our cylinder head flow numbers and how they measure up. As a leader in the 951 market, we often set the benchmark that our competition or critics try to compare with.With that being said... We will go on to explain through a small presentation that will help you to better understand how our flow numbers are obtained and presented. Our goal is also to educate you to make sure that when you're comparing our head's flow numbers to someone else's or you hear of someone who is boasting greater knowledge or skill in the field, that you will be better able to judge for yourself who is qualified and who may be pulling your leg, hoping that you are uninformed and uneducated on this subject. The methods in which we present our flow numbers are not only accurate, but also right on the money. No games or tricks. We are the only company that we know of that does quote flow numbers. Why is this? Because we can back them up. In an effort to stay ahead of the competition and eliminate any doubts, we have flowed heads from several competitors to know that we are doing a better job than anything we have come across to date. We have tested heads from Arizona, Southern California and Tennessee. If you have a head you would like flow tested, feel free to send it to us and get the real scoop. No Charge! When we are in the process of designing a product, we not only use our own experiences but we also rely on the professional community around us and the experience of our vendors to produce a product that will not only perform, but also is affordable. When we quote specifications be assured they are from actual testing done by professionals in their prospective field because we feel those specifications are crucial in making wise purchasing decisions. Our "Flow Guy" is hard to beat because he has almost 40 years experience doing flow work as a full time occupation. So please sit back, read on, and learn a little more about flowing cylinder heads and presenting flow numbers in a reputable and honest fashion. At the same time, you will also learn why others may get larger or smaller numbers depending on their equipment, procedures and atmospheric conditions. Here in Oklahoma City we are at 1200 feet altitude. But we don't always see weather conditions that equal 1200 feet. We are often in air equal to 3000 feet. The higher the altitude, the lower the flow numbers. The lower the altitude, the higher the flow numbers. Since we are in Oklahoma, we post flow numbers reproducible here. I'm sure there are parts of the World where our numbers would appear high, and just as likely places where they would appear low. But again, we are in Oklahoma at 1200' and not somewhere else. This particular testing day was not optimal for flowing heads to achieve maximum numbers. Our flow guy would normally on a day such as this only rough in the port and do the finish work on a better weather day. The weather conditions on this morning were equivalent to over 4000' above sea level and not good air for doing flow work. Unfortunately, we didn't have the luxury of waiting for a good day with our schedule so we will work with these. We will use two different flow rates for this example. Both 10" of water column, and 28". This will show that you cannot compare flow numbers at two different flow rates. We use 28" because it's not only an industry standard, but we want to put as much air through the port as possible to simulate the airflow when under boost. Even at 28" of vacuum, there is less air than in the real boosted world. But more is better for the purposes of porting and testing. We feel that even at 28" you're only simulating about 2-3 psi of boost. 10" would hardly be 1 pound of boost.

Beginning conditions:

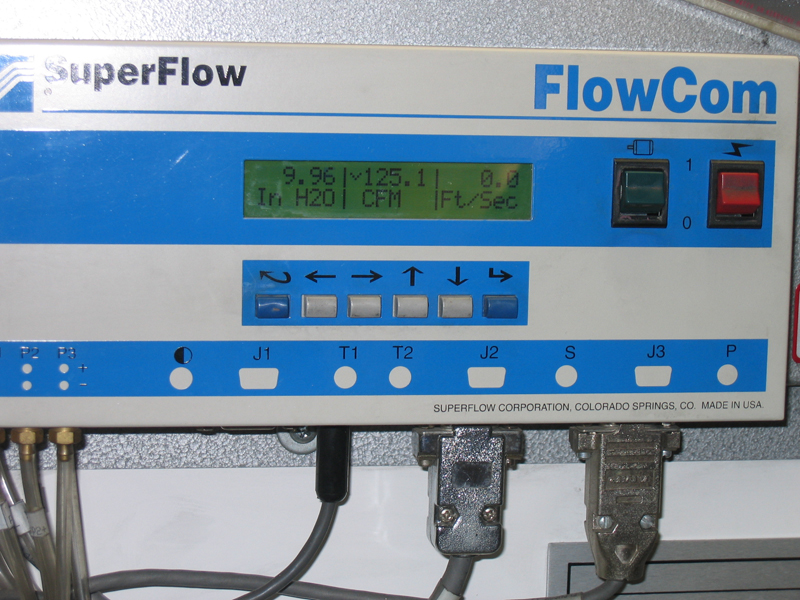

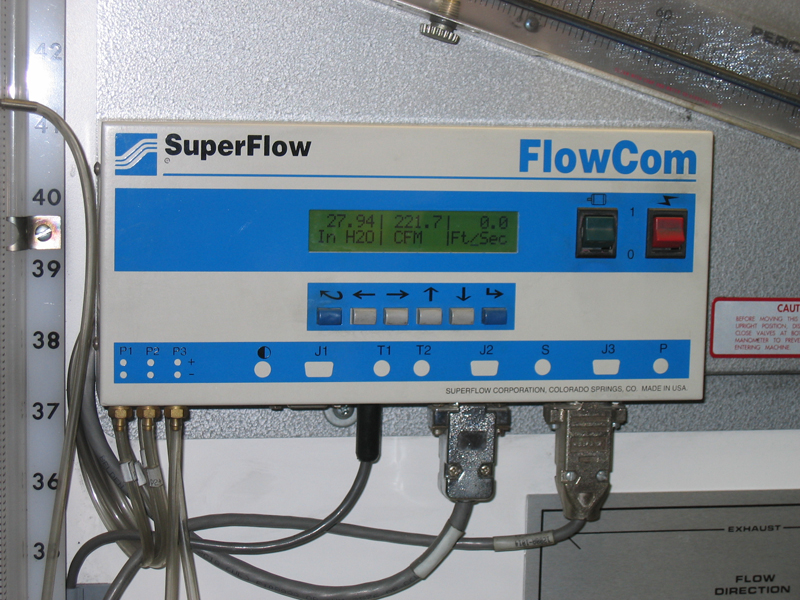

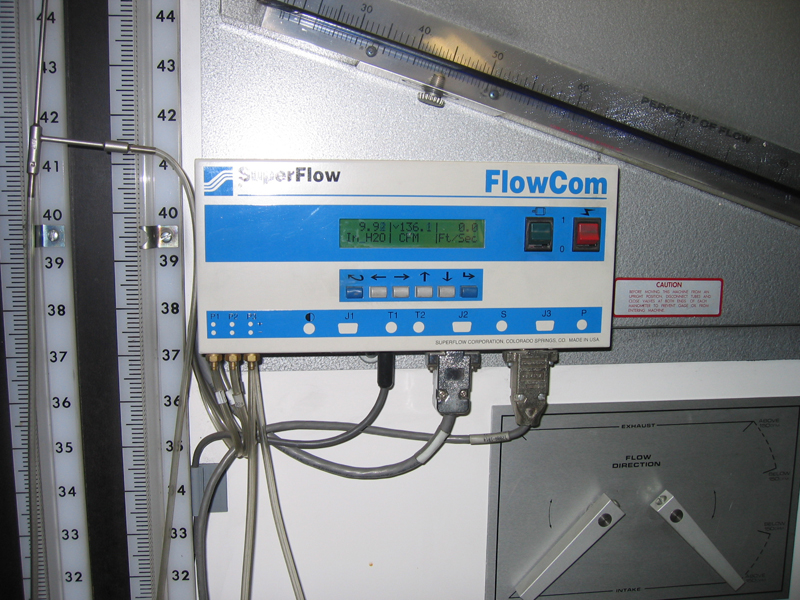

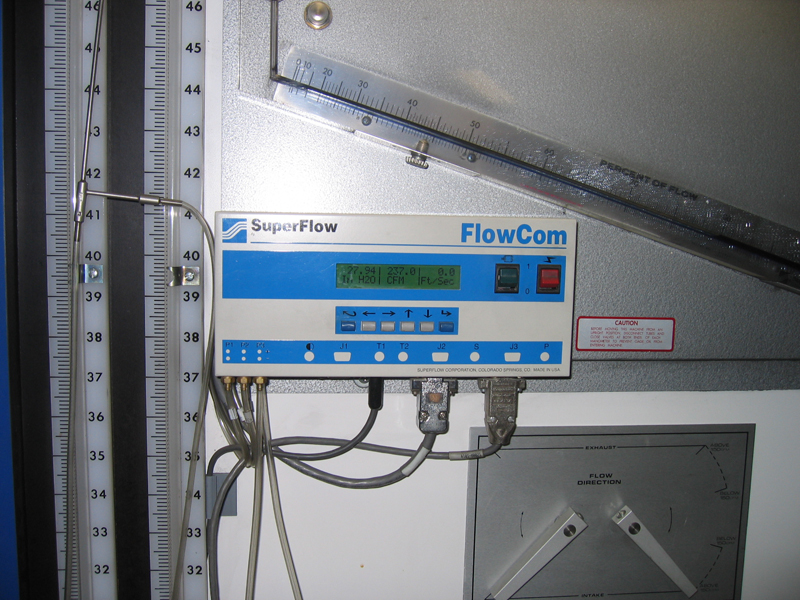

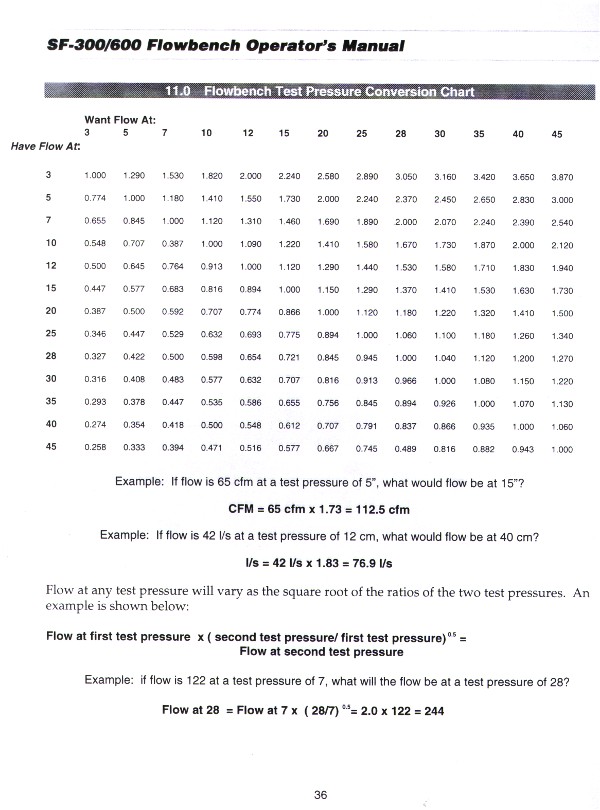

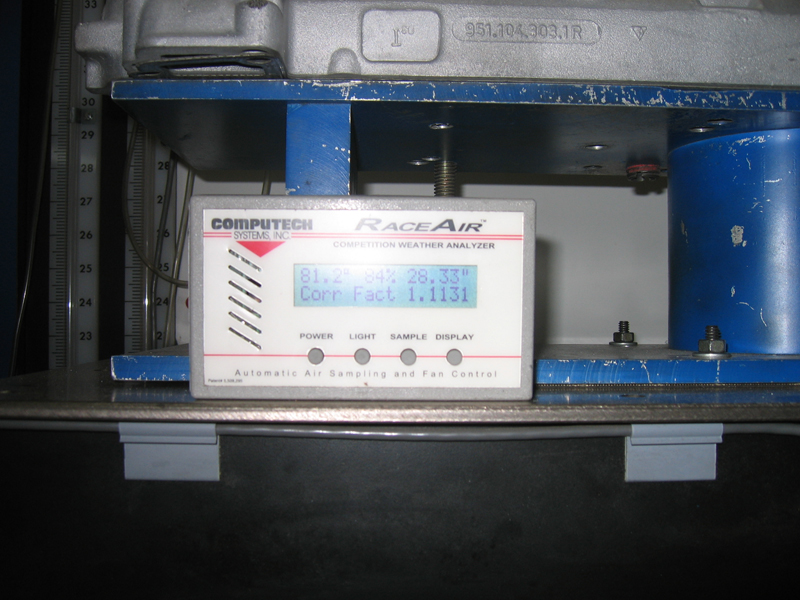

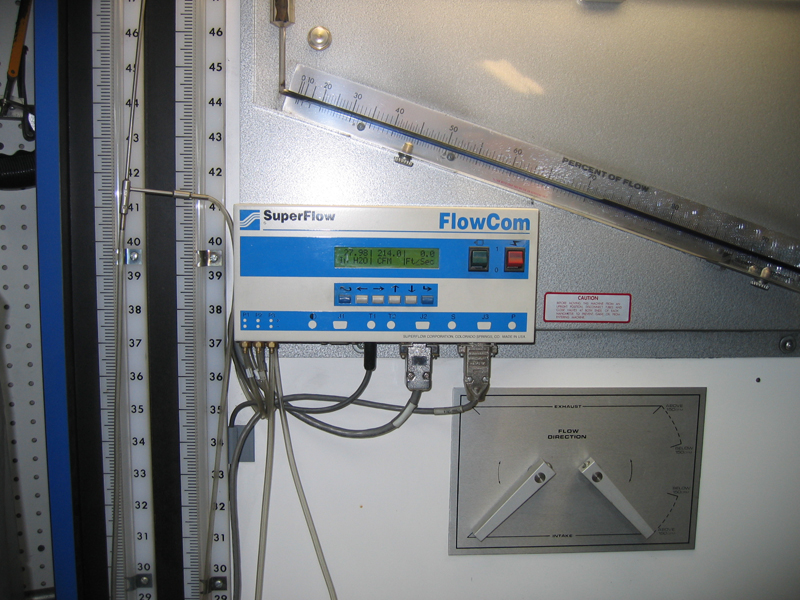

Ending conditions: On this morning, first we take one of our Stage II cylinder heads. We first flow the head at 10" of water column, then at 28" of water column. These two tests are done within 60 seconds of each other. All set-up and conditions are identical. When we flow the Stage II head at 10", the results are 125.1 CFM. When we flow the Stage II head at 28", the results are 221.7 CFM. We then flow the Stage III head at 10", the results are 136.1 CFM We flow the Stage III head at 28", the results are 237 CFM. We use a flow bench with the air necessary to flow at 28" of water column. If using a machine with only 10" of water column, which is not the industry standard of measurement or comparison, then you would be using a much smaller machine such as the Super Flow SF110/120. Flowing at 10" is just not going to cut it when trying to work at the air flow we see in these heads. Now we turn to the Super Flow manual that comes with the Super Flow SF600 flow bench. When we flowed the Stage II head at 10", and do the math to convert to 28", (125.1 x 1.670) we get 208.9 CFM. But the head actually flowed 221.7 CFM 60 seconds later on the same machine cranked up to 28". When we flowed the Stage III head at 10", and do the math to convert to 28", (136.1 x 1.670) we get 227.28 CFM. But the head actually flowed 237 CFM 60 seconds later on the same machine cranked up to 28". As you can see for yourself, the conversion calculations do not equal what is actually happening in the real world where Lindsey Racing is. You can take the conversion chart and toss it out the window. It just plain doesn't work on a 951 or 944 8v cylinder head. Keep that in mind when others rate heads at lower flow rates and try to compare to ours flowed at 28". Whether you flow at 10", 25", 28" or some other vacuum level, it's only a flow rate chosen as to be your repeatable environment. The equipment may dictate this flow rate. This allows you to compare your own work, from one head to another or one port to another. The flow rate you choose is not all that important, although more is better on a boosted car. What is important is that you use the same rate for all your comparisons. You cannot as we have shown test one day at 10", then another at 28" and expect to have reliable information for measuring your progress, good or bad. Now are you wondering why our numbers here are still shy of our advertised numbers? Time to consider weather condition factors. The one variable that can change from day to day, and even hour by hour that can effect the results. Our Flow Guy uses a Computech Weather Station. At the time of our testing on the heads above, when we started we were at the equivalent altitude of 4224 feet above sea level. 50 minutes later when we finished our flow work, we were at the equivalent of 4472 feet. The weather conditions for flowing went from bad, to worse. Don't forget, we are actually at 1200 feet. The humidity was also high which is not good for testing. Flow benches flow air, and do not like to flow water. The Weather station gives you a correction factor that is used to calculate to Sea Level. When you use the correction factor of 1.115 (the two averaged during today's testing) from the Weather Station, our Stage II head flowed 247.19 CFM and our Stage III flowed 264.25 CFM at "Sea Level". Numbers that are far greater than we advertise. Numbers we could easily be using. But we choose to not even go there with the Sea Level conversion because, again, Lindsey Racing is at 1200 feet. If we had weather conditions we normally see this test day, the numbers would of been 1 or 2 CFM either side of our advertised numbers. We know that from our experience and the sheer numbers of heads we test, flow and sell. We must admit we haven't figured out how to change the weather yet to accommodate our schedule. We post CFM numbers not so much to show the actual CFM, since that can change with a variety of variables as we have shown, but to show the percentage of improvement from one head to another. From a stock head to a Level I, to a level II to our level III. That's a number that will remain consistent regardless of the variables if all testing is done in the same manner. We choose to test in the same manner, in similar weather, with identical inlet guide, and the same "Flow Guy" doing the work. You might ask yourself again, could someone else get different numbers if they tested the same head? Sure they could. Aside from what we have already shown, there are many other variables. Right from the Super Flow manual they state the following testing errors to avoid. These are things the same Flow Guy would want to do, let alone someone else being able to produce the same identical factors somewhere else for accurate comparisons.

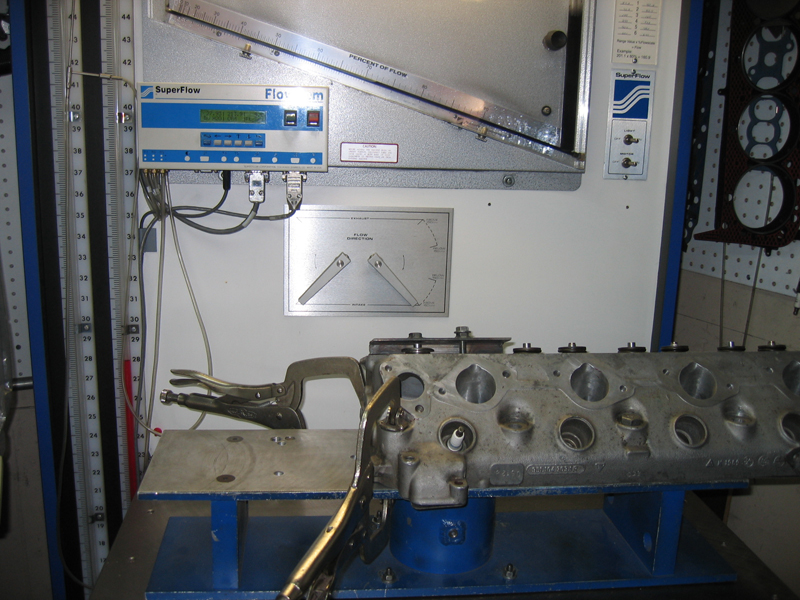

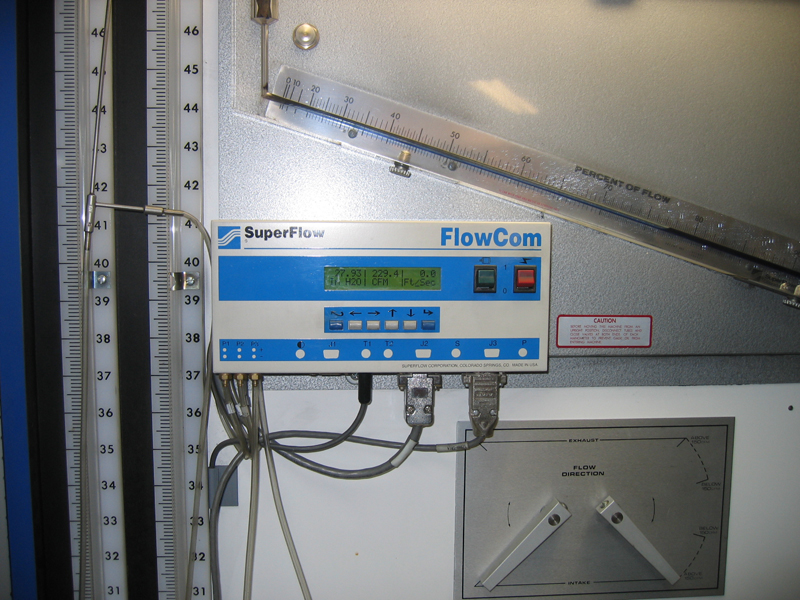

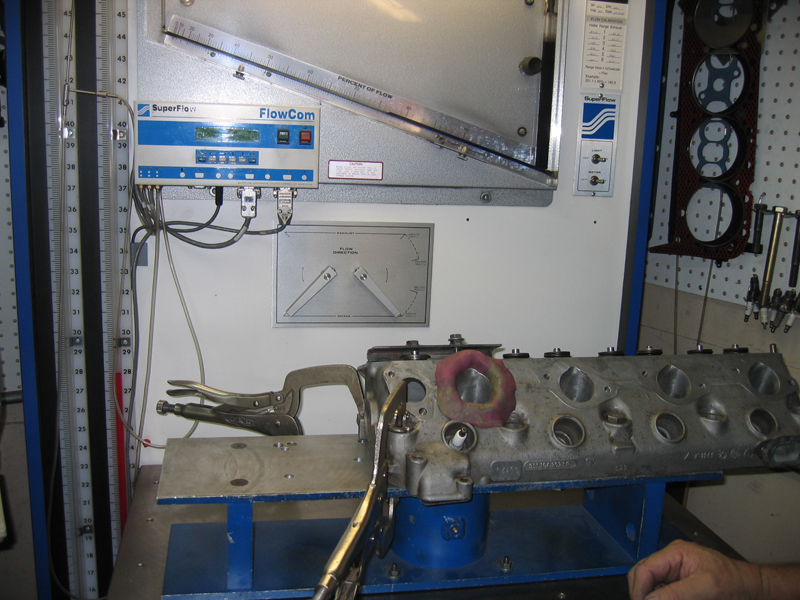

1) Always use the same orofice range at the same test point. Item 5 is a very interesting point where some don't realize the importance. If you're testing a head or comparing one to another, without the same inlet guide, the numbers will vary. We will show you an example. A customer sent us a Big Valve Head built by someone else to test and determine whether or not to use it or start over with another one on his project. This head was used on a IMSA GT car and is fitted with a huge 51mm valve on the intake. You can also see the level of work on the head by looking at the valve retainers with their Inner Spring Oil Cooling modification. Clearly the work of a high end shop. Or so you would think... Here we test the head at 28" "WITHOUT" an inlet guide. Here we test the head at 28" "WITH" a inlet guide. The head without the inlet guide flowed 214 CFM. The same identical head 2 minutes later with a "quickie" putty inlet guide flowed 229.41 CFM. Point to be made here is if you flow a head without an inlet guide and compare it to one where one is used, the comparison is not accurate. The air will not flow around the sharp edge of the head cleanly. When the head is in the real world, the intake manifold runner feeds the port and becomes the inlet guide. However it would be impossible to work the port with the intake in the way so a guide is used. Different inlet guides will net different flow numbers mainly because of the different radius of the opening. So unless you have the indentical inlet guide, comparisons will also be false. Lindsey Racing uses a custom manufactured Inlet Guide when flowing heads. This allows us to go from one port to another and one head to another and maintain consistency and repeatability on any given day.

Lindsey Racing also uses a cylinder adapter. That's the blue pair of plates with the round tube between the two. That tube represents the cylinder. The larger the tube, the more the flow. The smaller the tube, the less the flow. This tube is machined to 100mm on the ID bore. The same as the 951's bore. If any of these heads were bolted to a 100.5mm bore, or even a 968 block with a 104mm bore, the CFM through the head would increase. Someone using a cylinder adapter with a bore smaller than 100mm, the flow numbers would be less. .060" can make a difference of several CFM. So in order to compare one head to another, the same adapter must be used. We also do all our testing at .480" of valve lift. If tested at a different lift, the numbers would be different. If the valves and seats were cut different, that would also change the flow numbers. In case you're curious how this customer's Big Valve head performed, it flowed between our Stage II and Stage III which uses a smaller valve. This is a good example of the fact that just because you put a larger valve in the head, it may not equal gains in CFM. Often the valve is too close to the cylinder or perimeter of the combustion chamber to let the air flow around it. This goes to show that bigger is not always better. And without flow testing, one would hope the bigger valve was a improvement, but this shows it was not. At the time we tested the above heads for the 10"/28" comparison, we were not getting weather conditions that were cooperating or favorable for good numbers. We decided to have our Flow Guy test the same intake port on the same head, on the same flow bench, with the same inlet guide, with the same head plate, at the same 28" of water column, over period of time to illustrate the variance you get with weather. Below you see the results of 12 different days from October 15 thru November 2nd 2005. This is the same port and head as the above testing. We show the Date, CFM of air flow through the port, Humidity, Correction Factor from the Weather Station, Ambient Air Temperature in Fahrenheit degrees, Corrected Altitude & Air Density Ratio.

The port on this Stage II head during this period flowed a low of 227.2 CFM to a high of 234.1 CFM. A difference of 6.9 CFM with everything else being equal except the weather. We saw 221.7 CFM earlier on our 10"/28" testing with the same cylinder head and port. That would make the net difference of 12.4 CFM. You can see for yourself how the weather has an effect on flow numbers even when nothing else changes. You will see us change our advertised Stage II head CFM flow from 232 to 234 CFM based on these results since the weather conditions were very close to actual altitude. After all, if you did 10 dyno pulls, you wouldn't advertise your worst HP figures. If you did 20 laps at Sebring, you wouldn't advertise your slowest lap time. If you ran 5 13.00s at the drag strip, then ran a 12.99, you would say you had a 12 second car. So there you go. You learned a little more about presenting flow numbers and how they can vary or be altered from one source to another. So if you see anybody claiming that their heads flow better than ours, especially if rated at different inches of water column, in a different part of the world, with different inlet guides and cylinder adapters, with different weather conditions, consider everything you have learned here and you be the judge. Even if flow numbers are presented at the same flow rates between two or more companies, it's easy to now understand how you cannot give the comparisons any credibility. You need to ask yourself who you trust and who you don't. Who can back up their information, and who cannot. Who can speak from years of experience, and who cannot.

|

Secure Checkout